Coupling Half

Machine Used : Turning Center | Cycle Time : 38 Minutes |Material : EN 8 |Application : Automotive | Dimension : 42 x 20 x 92mm Ø

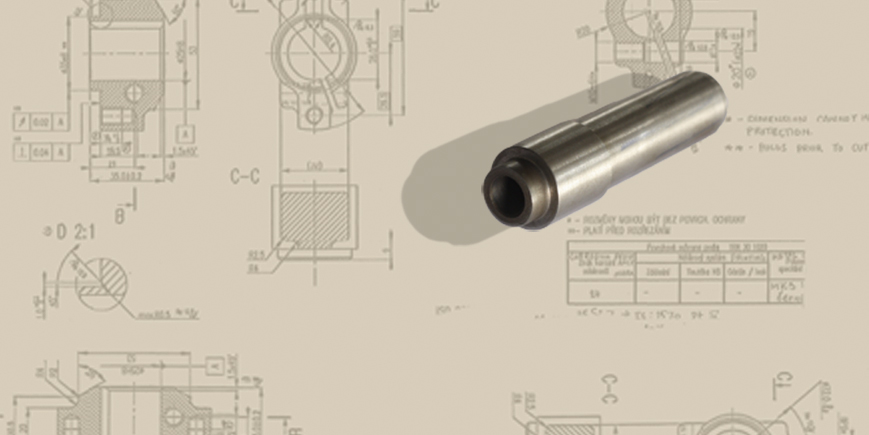

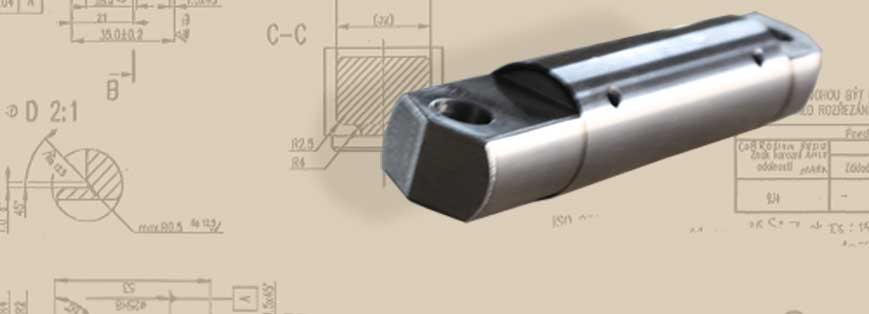

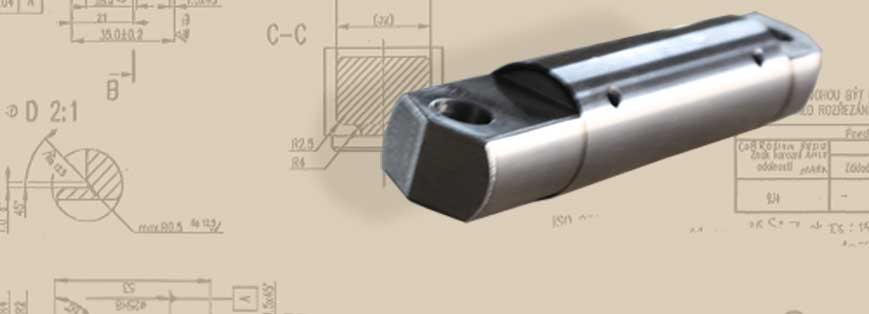

Cam Follower Shaft

Machine Used : Turning Center,VMC |Cycle Time : 26 Minutes |Material : SAE 1860||Application : Earth Moving | Dimension : 183 x 36mm Ø

Below the Knee Prosthetic Adaptor(BKP)

Machine Used : Turning Center,VMC |Cycle Time : 35 Minutes |Material : Stainless Steel |Application : Medical

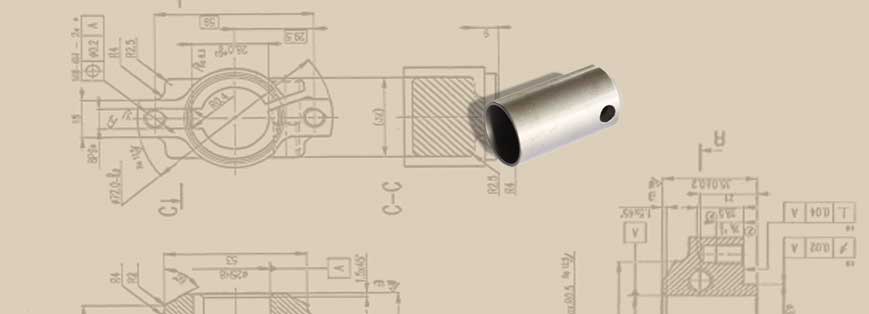

Ventilator Shaft End Flange

Machine Used : Turning Center,VMC |Cycle Time : 21 Minutes |Material : Low Carbon Steel | Application : Automotive | Dimension : 42 x 60mm Ø

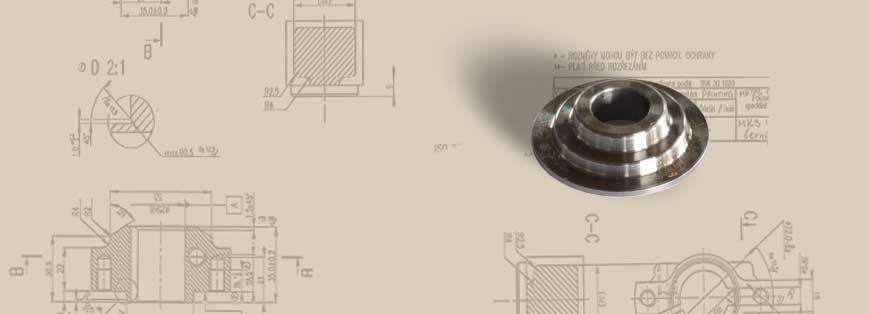

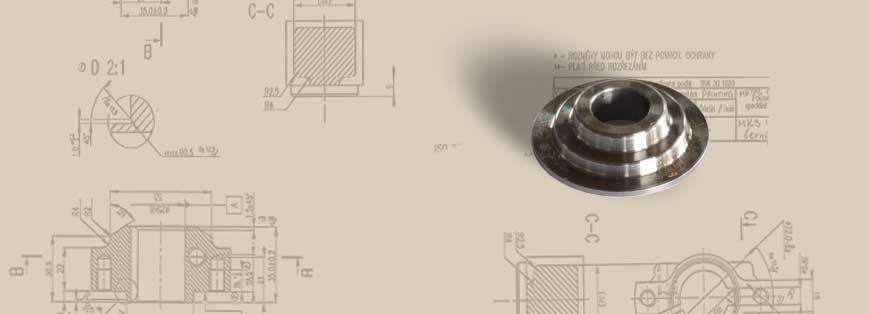

Valve Spring Retainer

Machine Used : Turning Center|Cycle Time : 6 Minutes | Material : SAE 8620 | Application : Automotive | Dimension : 42 x 60mm Ø